Fibrous glass duct wrap insulation is designed for application to the exteriors of commercial and residential sheet metal heating ventilating and air conditioning ducts and plenums operating at temperatures between 40 f 4 c and 250 f 121 c.

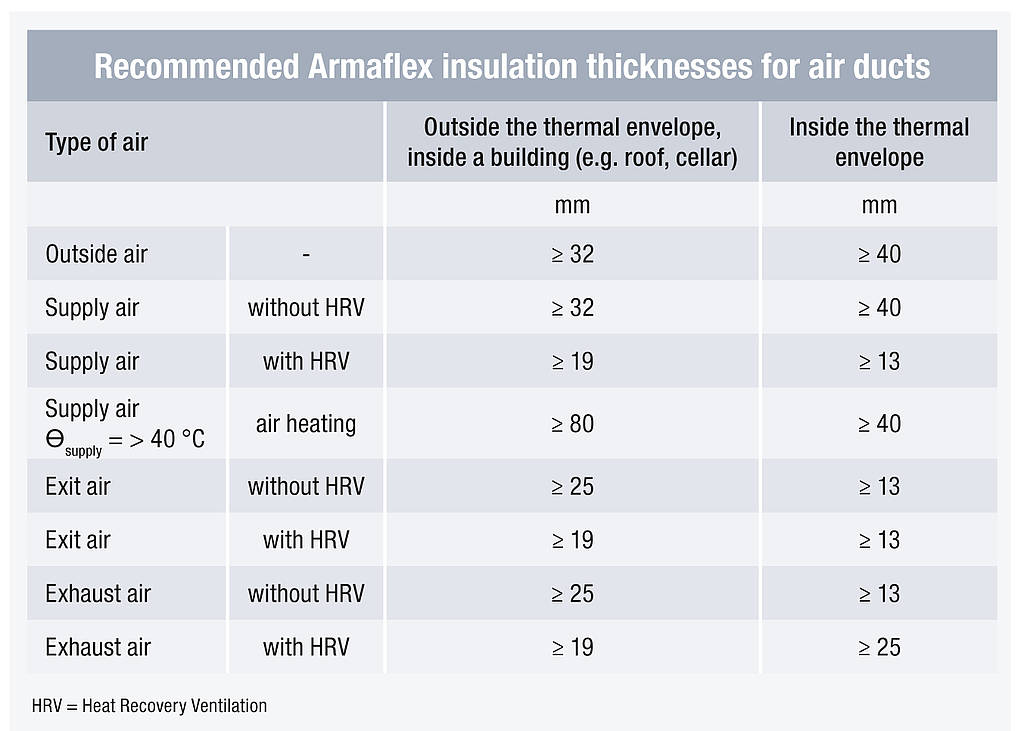

Air duct insulation thickness.

Some of the most reviewed insulation are the master flow 6 in.

Enter the flow rate of the air carried by the duct in cubic feet per minute.

Much like an insulating thermos duct insulation with a good r value will create a barrier between different air temperatures to prevent the unwanted heating or cooling.

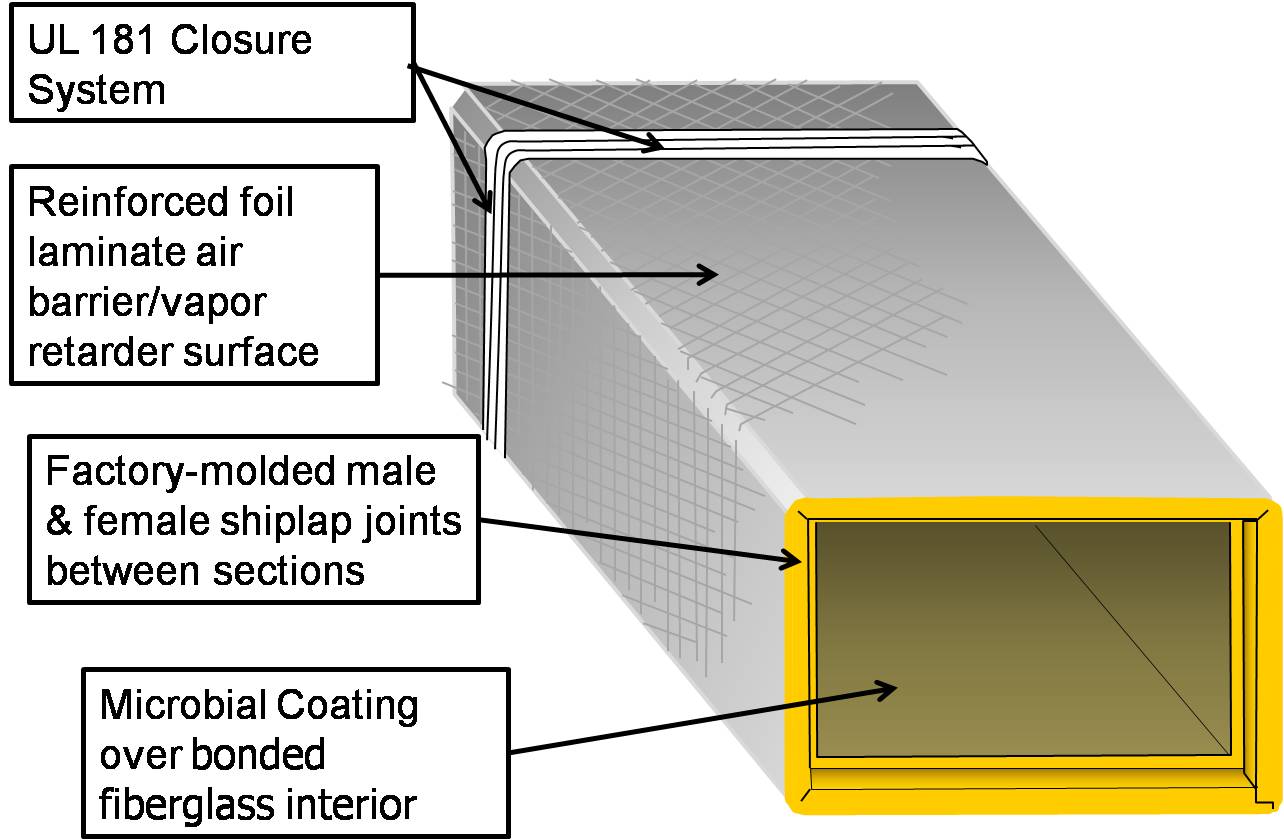

Cut this duct board to size and use it to build your own hvac fittings or trunk duct and then assemble it with fiberglass weave and mastic or duct board approved duct tape for a convenient solution to your ducting problems.

Foil and fiberglass duct insulation with 116 reviews.

Dia r 6 ductwork insulation sleeve with 125 reviews and the frost king e o 12 in.

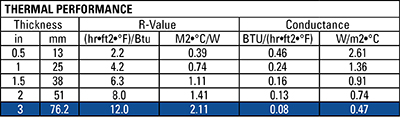

The most effective type of insulation is one that is thick dense and allowed to take up space giving it more room to create a barrier between the ducts and the outside air.

Duct wrap insulation reduces heat loss or gain through duct walls conserving energy.

The master flow 48 in.

Fabricated into the duct itself duct board offers both sound and thermal control.

Enter the perimeter of the duct in inches.

Duct board r 6 features fiberglass construction with an fsk backing for sturdiness over time.

Thermal insulation installed on the outside of sheet metal ductwork helps to increase the efficiency of the system and with fsk facing can aid in the condensation control design of a system.